What is electromagnetic compatibility?

Development of electronic circuits goes hand in hand with the need of electromagnetic compatibility compliance. To have a product placed on the EU market, depending on the type of the product a technical conformity dossier must be prepared and the CE marking must be placed on the product.

As a manufacturer you don’t need any license to declare the conformity and affix the CE making but you have to make sure your product meets all of the relevant EU requirements. One of the requirements applies for electronic products is the EMC directive. See this here (https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32014L0030&from=EN).

This directive says: “Directive 2014/30/EU on Electromagnetic Compatibility (EMC) specifies in detail the essential requirements the product has to meet in order for the manufacturer to affix the CE marking. Directive 2014/30/EU is intended to ensure that equipment liable to generate or to be affected by electromagnetic disturbance can be used in the electromagnetic environment for which it has been designed without causing disturbances to other equipment or being affected by them.”

The optimal way to get certification

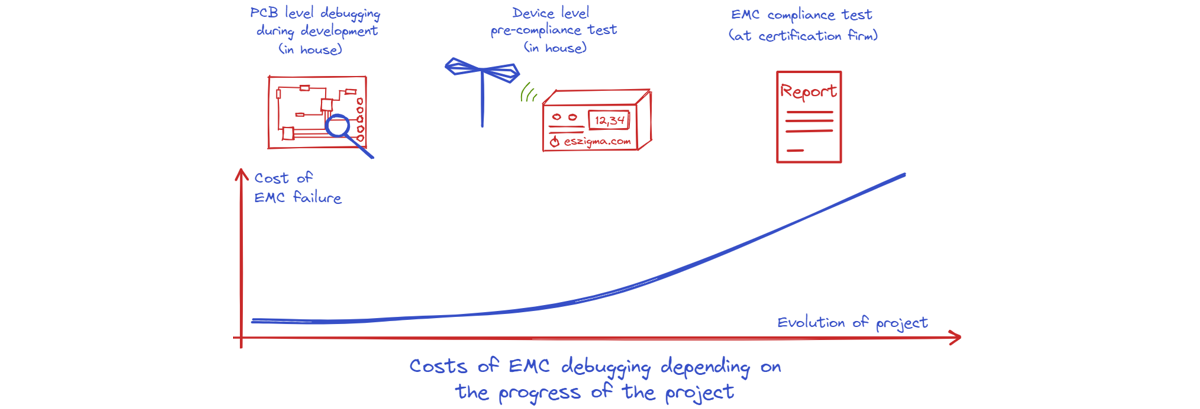

To make sure the product under development will pass the EMC compliance test at a certified test house we have to pay special attention to the electromagnetic problems early in the design cycle. The earlier an EMI problem is solved the more cost effective and easy it is. Plus, the developer has a wider variety of technical intervention. The figure below shows that is worth to perform EMI tests either on board level or device level early at the design cycle. If compliance testing reveals an EMC failure the repair is definitely expensive and will probably delay the time to market. Also note that neither EMC test lab can’t tell you where the problem is exactly coming from because they cannot locate such in a completed device.

How we can help you?

Our company pays special attention to the facts above so that only that product or circuit can proceed the design phases that are proven to meet the EMI expectations (and not the standards as we are in the design cycle) so EMI weaknesses won’t escalate later.

As part of our EMC pre-compliance testing service we make you the opportunity to get a detailed view of the RF emissions and RF immunity performance of your circuit or device be in any phase of development prior to a costly compliance test.

As part of our EMC consulting service we can help you resolve any EMC related issues you’re your product or circuit.

EMC pre-compliance tests |

|

|

In our pre-compliance measurement service, we first identify all the standards required to the customer’s device to see the different emission and immunity test levels. To perform immunity tests we have to beware the operation of the device that means we need some interaction with the customer We perform radiated emission and immunity tests in GTEM cell and conducted emission and immunity with RF current probes. |

EMC debugging and consultancy |

|

|

In case our measurements reveal any EMI related issue in customer’s device than we offer our EMC debugging service. This service is even available in the early stage of your product development to achieve EMC compliance. To debug a device or a circuit we have to dive deep into the details of the circuit to interfere with the operation so high customer interaction is needed. We understand that principles of operation and schematics are confidential and crucial for you so we always sign confidentiality agreement. In most of the cases EMI debugging and consultancy results in PCB- or component-level modifications in collaboration with the customer We have a wide variety of EMI debugging tools. Using TEM cells, RF current probes, near-field probes, AC and DC LISNs and also RF instruments are a daily routine for us. |

ESD testing |

|

|

Thanks to our EN 61000-4-20 compliant ESD test station we can inspect electrostatic discharge immunity of your electronic device. Consultancy and debugging service is also available. |